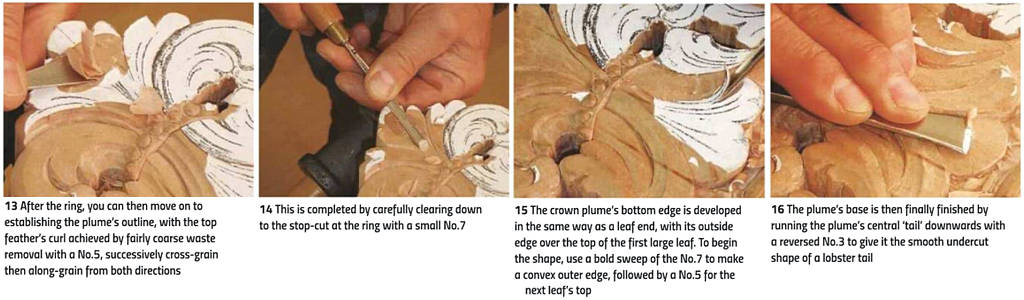

In my book, and elsewhere, you’ll find a series of ‘feeder’ projects, which will facilitate the development of carving skills; however, the one shown here is the sort of ‘useful’ project you should be aiming towards. The pattern may need adjusting to suit your choice of clock mechanism – in my case, a 160mm (6½in) clock face – to ensure that it’ll fit within the carved bevelled ring.

As the timber I used wasn’t thick enough, I took offcuts from a birch slab and glued these to the back in order to increase the piece’s thickness and to bulk up the side profile. The enlarged pattern was then stuck to the blank, using spray-mount, and a hole for the clock mechanism cut with a hole saw, prior to roughing-out the pattern using a bandsaw, mounted with thin blade, although a coping saw can also be used.

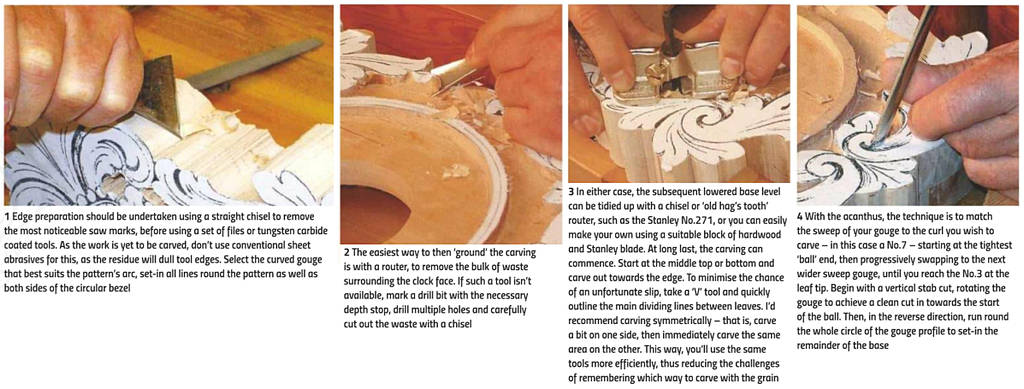

Just remember to make ‘relief cuts at suitable points around the pattern, which will allow the waste to drop away without jamming the saw blade. In this case, I’ve undertaken what could be called an ‘initial finish’ on the sawn edges, as the pattern will be carved over and round the edges, so a near final edge is therefore required.