Scratches on your beautiful epoxy resin creations? It’s a common problem. Both artists and customers know the headache of a pristine surface quickly becoming marred. But don’t worry! This guide will explore various finish coatings to help you achieve a durable, scratch-resistant surface that lasts. Let’s look at what you can Coat your resin with to prevent scratches.

Ever made something cool with epoxy, only to find it gets scratched or looks dull over time? It’s frustrating, right? An epoxy resin topcoat is your answer. It’s like a shield, making your project look awesome and last way longer. Think of it as the final touch that takes your work from “meh” to “wow!” Topcoats add toughness, fight sun damage, and give the exact sheen you want.

Why You Need an Epoxy Resin Topcoat: Beyond the Initial Pour

Pouring epoxy is just the first part. A topcoat makes it truly shine. Lets explore why an epoxy resin topcoat is a must-have. It’s not just about looks, it’s about making your project last.

Protection Against Scratches and Abrasion

Epoxy can scratch easier than you think. Everyday use can leave marks. A topcoat acts like armor. It guards against scratches and wear. Some topcoats are tougher than others. Polyurethane topcoats, for instance, offer great scratch resistance. They keep your epoxy projects looking new, longer. Imagine a tabletop – a topcoat keeps it safe from keys, cups, and more.

Enhancing UV Resistance and Preventing Yellowing

The sun’s rays can harm epoxy. UV light makes it turn yellow over time. This is not a good look! A UV-resistant topcoat blocks those harmful rays. It keeps your epoxy clear and beautiful. Look for topcoats made for UV protection. This will prevent yellowing, keeping your project vibrant. Think of it as sunscreen for your epoxy!

Understanding Your Options: Finish Coatings for Epoxy Resin

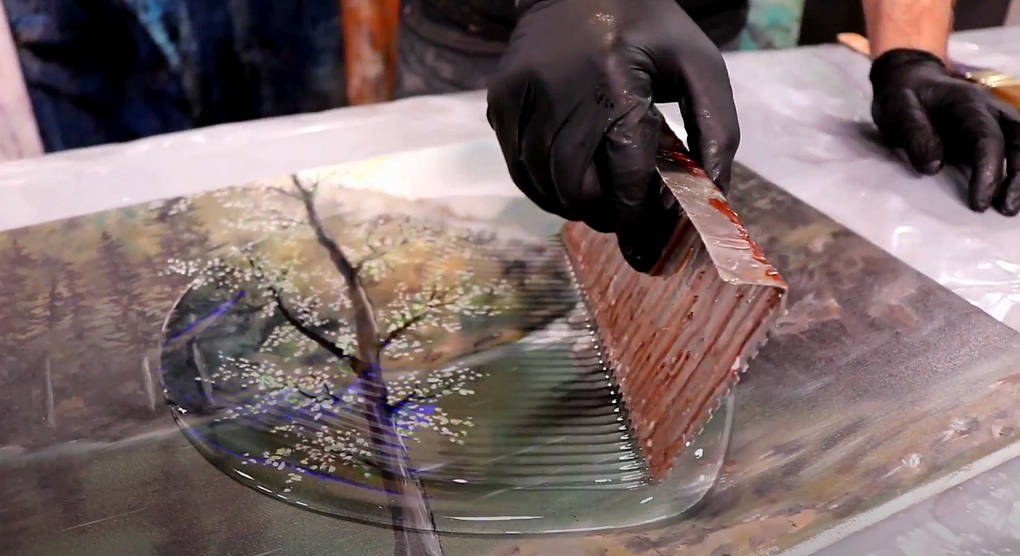

Let’s dive into the world of finish coatings. We’ll cover everything from classic epoxy to a surprising experiment with car polish. Each option offers different benefits and drawbacks. Which one is right for your project?

Epoxy Resin Finish: Deep Gloss, High Risk

A final coat of epoxy resin creates a stunningly deep, glossy finish. It’s like looking into another dimension! This coating completely seals your piece. It protects it from dirt, dust, and moisture. Plus, it really makes colors pop!

However, here’s the catch: epoxy resin scratches easily. Really easily. Think of it like this: it’s beautiful, but delicate. And if that weren’t enough, it can turn yellow over time, especially without proper UV protection. Consider using a UV-resistant epoxy, or applying a UV protective coating!

Glossy Polish: Shine With Caution

Glossy polish enhances the texture and color of your epoxy resin creation. It can bring out the natural beauty of the underlying material, like wood. A smooth, polished surface is also easier to clean. Dust simply wipes away!

But choose your polish wisely. Not all varnishes play well with epoxy resin, or with the material beneath. And be warned: glossy surfaces show everything. Fingerprints and scratches become glaringly obvious.

Matte Polish: Aesthetic Appeal and Scratch Resistance

Imagine a finish that’s soft to the touch. That’s matte polish. It’s hard to capture on camera, but it creates a velvety, almost corduroy-like feel. Many describe it as a plush effect. It’s a unique aesthetic that many find appealing.

Matte polish offers some serious advantages. It hides fingerprints, scratches, and dust remarkably well. In fact, it offers maximum resistance to these kinds of blemishes.

But there’s a trade-off. Matte polish can diminish the depth and dimension of your epoxy resin. If you’re aiming for a 3D effect, this might not be the best choice. However, if you want a durable, beautiful finish that minimizes imperfections, matte polish is worth considering.

Floor Polish: Durability for High-Traffic Surfaces

Floor polish? Yes, you read that right! Floor polish is designed to withstand heavy use. It’s adapted for intense loads. This makes it a surprisingly good option for epoxy resin surfaces.

Floor polish often repels water and dirt. This is a huge plus, especially for countertops or kitchen surfaces. It’s also available in matte, semi-matte, and glossy options, giving you flexibility in your final look.

However, floor polish has its downsides. It typically requires a long drying time. And it demands thorough surface preparation. If you’re willing to put in the extra effort, you can get a very durable finish.

The Secret Experiment: Car Polish for Epoxy Resin

Now for something completely different… I’ve been experimenting with car polish! Yes, car polish. The claim? It does not scratch and leaves no trace of hot items!

This is still in the testing phase. But if it works, it could be a game-changer for epoxy resin artists. Stay tuned for a future update with detailed results. I’ll share everything I discover.

Choosing the Right finish coatings: A Quick Comparison

Here’s a quick rundown of the finish options. Consider the pros and cons of each to decide which suits your project needs:

| Finish Type | Pros | Cons | Best Use Cases |

|---|---|---|---|

| Epoxy Resin | Deep gloss, 3D effect, seals and protects | Scratches easily, can yellow over time | Art pieces where visual depth is paramount, items needing complete encapsulation |

| Glossy Polish | Enhances texture and color, smooth surface for easy cleaning | Shows fingerprints and scratches easily, requires careful selection | Decorative items, surfaces needing frequent cleaning |

| Matte Polish | Hides fingerprints, scratches, and dust, maximum damage resistance | Diminishes depth and dimension | Functional items, surfaces prone to scratches, projects prioritizing durability over extreme gloss |

| Floor Polish | Durable, water and dirt repellent, available in multiple sheens | Long drying time, requires thorough preparation | Countertops, kitchen surfaces, high-traffic areas |

| Car Polish | TBD – Scratch resistance, no marks from hot items (Preliminary results) | TBD – Experiment in progress, results coming soon! | Potentially a wide range of applications depending on the experiment’s outcome. Keep in mind we still do not know the long term effects it has on epoxy resin or other surfaces. |

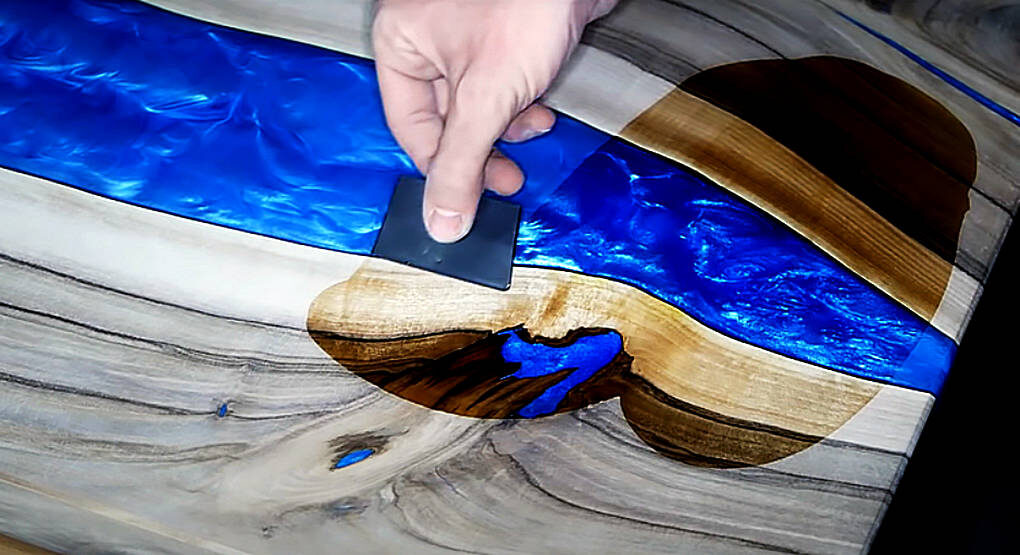

See how to make a resin table here.

Maintaining Your Epoxy Resin Topcoat: Cleaning and Care Tips

Taking care of your topcoat will keep it looking great. Here’s how to maintain it.

Regular Cleaning and Maintenance

Clean the surface often with a mild soap. Avoid harsh chemicals, as they can damage the topcoat. Use a soft cloth to wipe it down. Regular cleaning prevents buildup and keeps the finish clear.

Repairing Scratches and Minor Damage

Small scratches can often be buffed out. Use a scratch repair kit for deeper damage. Follow the kit’s instructions carefully. Blending the repair into the surrounding finish is key. With care, you can make minor damage disappear.

We have detailed resin safety tips on our website.

Conclusion: Towards Scratch-Free Epoxy Resin

An epoxy resin topcoat is more than just a finish; it’s an investment in your project’s longevity and beauty. Choosing the right topcoat and applying it correctly ensures lasting protection, UV resistance, and the perfect sheen. Protect your projects!

Finding the perfect finish for your epoxy resin projects is a journey. From the deep gloss of epoxy itself to the surprising potential of car polish, you’ve got options. By carefully weighing the pros and cons of each, you can create beautiful, durable pieces that will stand the test of time. Which finish will you try first?