Alan Holtham demonstrates how to make your own framed and panelled doors with a few pieces of standard kit

Profile scribing and panel moulding cutters for the router are widely available, making it quick and easy to produce traditional framed and panelled doors to a professional standard. The cutters are produced in a wide range of shapes and styles and are best suited for a variable speed 12mm capacity router as they tend to be on the large size.

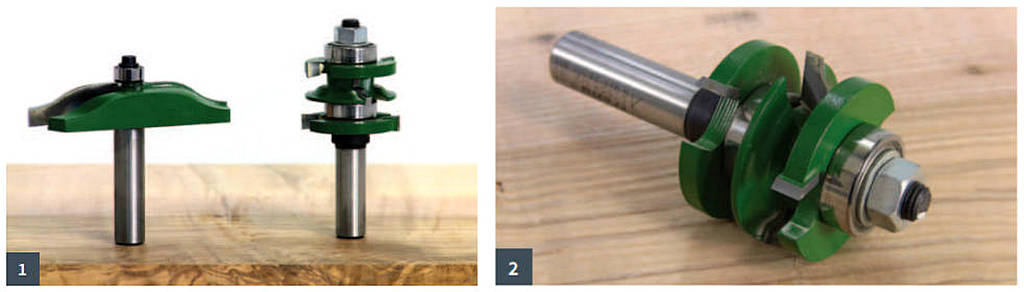

This door requires a standard cutter set, consisting of a single profile and scribe cutter and a separate panel raising cutter. Both the required profiles are produced with the single cutter by raising or lowering it in the table to use either the top or bottom half. Other sets have bits for each profile or interchangeable cutters that are swapped around on the same arbor.

The sides of the door are called stiles and the top and bottom components are called rails. The top one may be parallel or sometimes it is shaped into a cathedral or cambio pattern. If it is a big door there may be an intermediate stile called a muntin. The rails are jointed into the stiles with a scribed joint which matches the decorative stile edge.

The panel in the centre of the door can be solid or veneered ply or MDF and may be flat or raised into the traditional fielded shape. The mould varies from a plain bevel to an elaborate profile. The outer edge of the panel is sized to fit into the groove that runs all round the inside edge of the door.

Preparing the cutters

The profile scribing cutter is made up from several components, all of which are held on a precision arbor. Having cut the scribe on the rail ends, the profile block and groover are rearranged to cut the matching profile and panel groove along the inside edges.

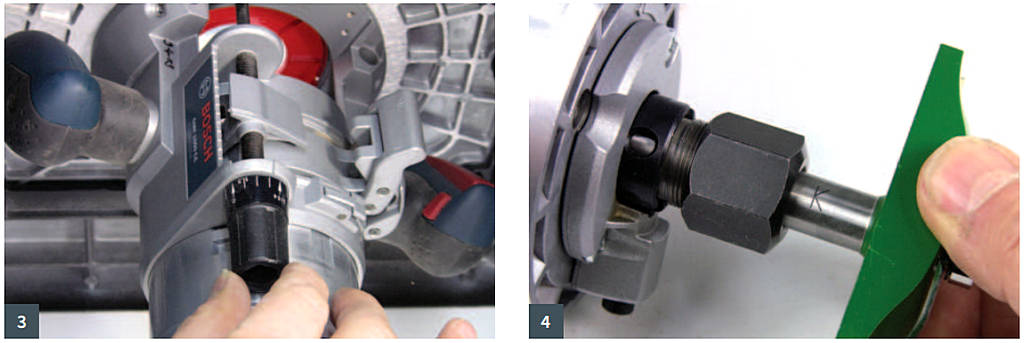

As you assemble the cutter, make sure that the individual knives are positioned at 90° to each other on the arbor to minimise vibration and produce a more even cut.

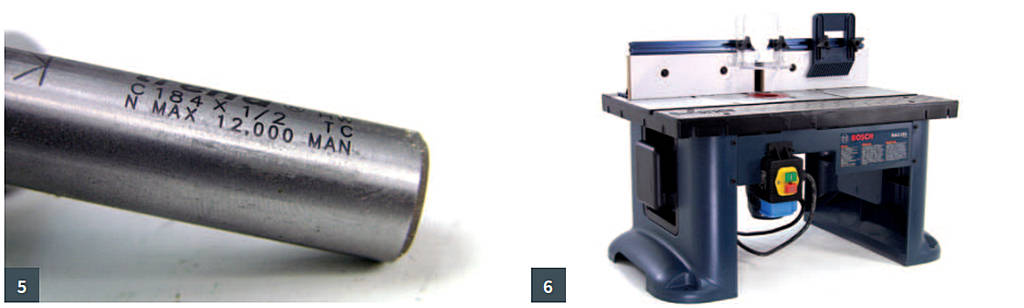

It is essential that your router has a fine height adjuster so that you can match the profile and scribe cuts perfectly. Make sure these big cutters are inserted up to the ‘K’ line. You must also adjust the router speed where the peripheral speed would otherwise be too high. Reduce to something like 12,000 revs, which should be clearly marked somewhere on the cutter.

The timber must be accurately thicknessed as the joints will never fit properly if there is any variation in size. As the setting-up procedure involves some trial and error, always prepare a couple of spare pieces to allow for test cuts.

The length of the rails needs to be calculated to allow for the stub tenon that is formed on either end. This cutter forms a 10mm tenon so the calculation is:

Rail length = overall width of door – 2 x width of the stile + 2 x 10mm

This dimension has to be determined exactly at this stage.

You cannot trim it in any way once the profiles have been cut.

Safety

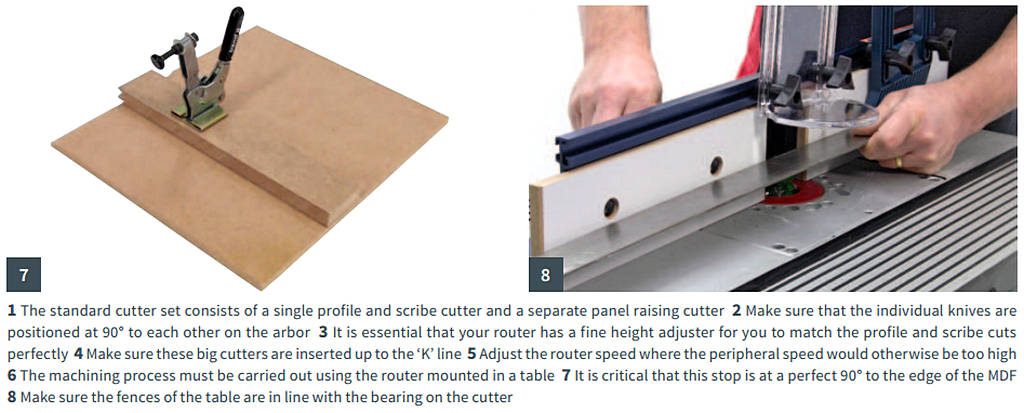

The machining process must be carried out using the router mounted in a table; you cannot do it safely or accurately enough using the router hand-held. Connect the table to a suitable extractor to minimise the dust produced as you work, this is particularly important if it is MDF being used.

Use the guards, hold-downs and feather boards to control the work safely when it is in contact with the cutters and all adjustments and cutter changes must be carried out with the router unplugged.

Cutting the joints

Start with the scribe joint on the rail ends and for accuracy and safety it is better to make up a guide jig for the rails. Even if your table has a mitre guide, it is still better to use the jig as it also minimises end-spelching as the cutter breaks through. The jig is a piece of 6mm MDF with a piece of 50 x 25mm glued on to act as a stop. The only critical requirement is that this stop is at a perfect 90° to the edge of the MDF. A lever clamp ensures the work can’t ‘creep’ as it’s being machined.

Make sure that the fences of the table are in line with the bearing on the cutter using a steel rule to line it all through and close them up to within 2mm of the cutter.

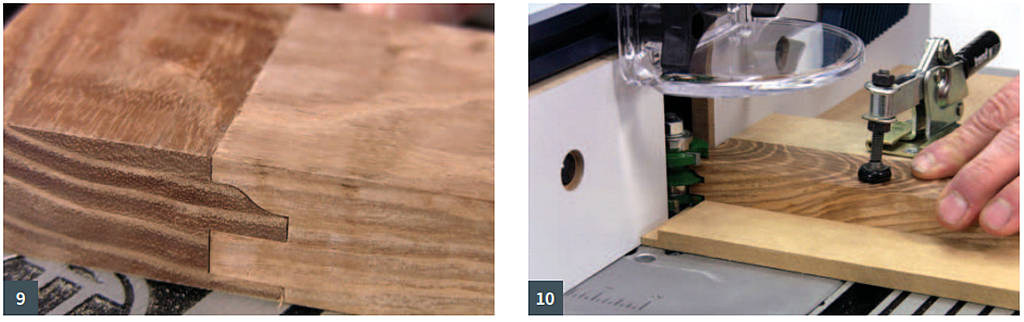

Set the height of the cutter to leave a minimum quirk on the moulding of at least 1.5mm. If it is less than this the edge will be weak or even lost when the job is sanded or painted.

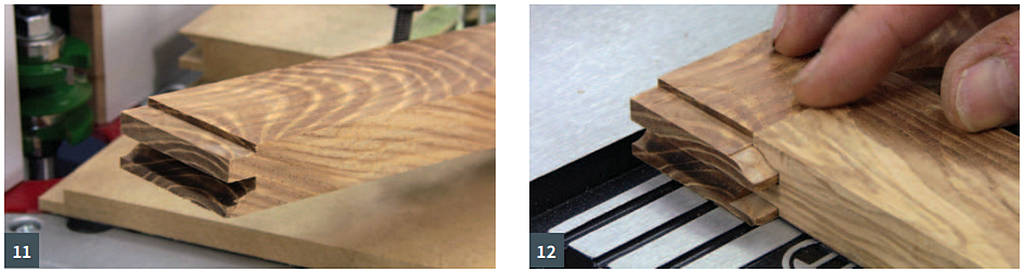

Clamp the rail to the guide jig face side up, making sure that both of them are tight up against the fence. Then slowly push the whole assembly through the cutter in a smooth action that is not too slow or the cutter will burn the timber. Keep the edge of the guide jig in contact with the fence all the way through and cut right into the end of the stop. This should minimise any breakout and the resulting joint should be really clean. Repeat the procedure on the ends of all the rails keeping them orientated correctly — face side up — for all the cuts.

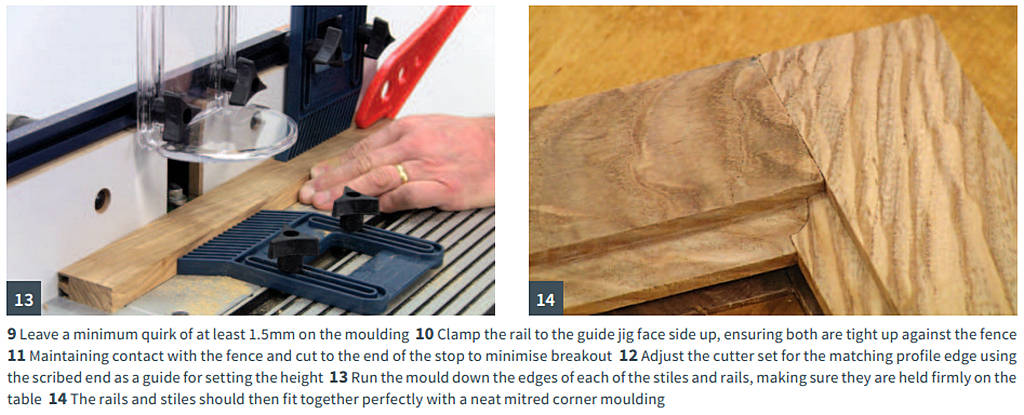

Now adjust the cutter set for the matching edge profile. Use the scribed rail end as a guide to setting the height and then make a trial cut in a piece of spare material and check it for fit. Note that these edges have to be machined with the face side down.

Run the mould down the edges of each of the stiles and the rails, making sure they are held firmly on the table or the groove will end up out of line with the edge. The rails and stiles should then fit together perfectly with a neat mitred corner moulding. You can cut the stiles to exact length after it has all been assembled.

Panel raising

The panel is next and if you are using solid wood you will have to make some allowance for it to move with changes in humidity. Any shrinkage and expansion will be greater across the width of the panel so leave about a 2mm gap at either side and 1mm at either end. If you are using man-made panels where movement isn’t an issue, just allow 1mm all round.

The panel-raising cutters are large in diameter so they may not fit through the aperture in your router table. If this is the case, make a false table from a piece of MDF and bury the cutter into this to achieve necessary height adjustments. Revolve the cutter by hand before you switch it on to make sure there really is enough clearance and check that the router speed is set correctly.

Start cutting the panel profile by making a shallow pass across the two ends of the panel and then down the sides to remove any breakout.

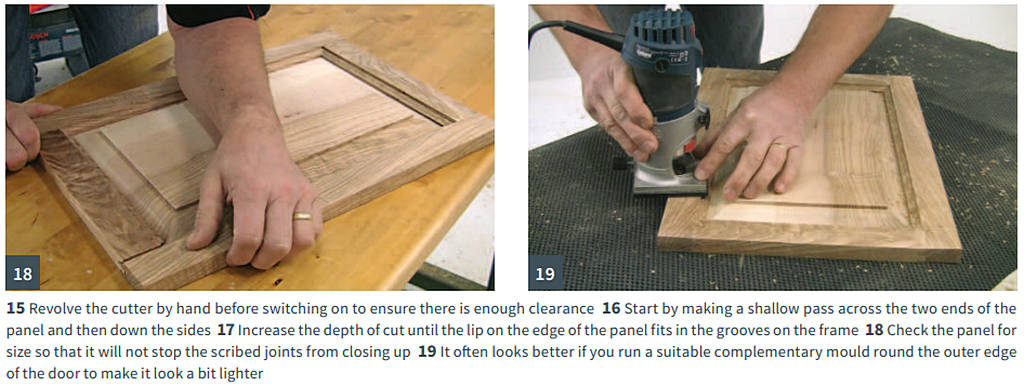

Keep increasing the depth of cut until the lip formed on the edge of the panel is a nice sliding fit in the grooves on the frame. Make a trial fit of the whole assembly just to check everything is in order and that the panel will not stop the scribed joints from closing up.

If everything is OK, glue the frame joints and clamp the whole thing together making sure it is square. You do not normally put any glue on the panel edges but leave it loose to allow for any movement.

A light sanding once it is dry will flush off the joints and remove any glue smears and your door is done. However, it may look better if you run a suitable complementary mould round the outer edge of the door to make it look a bit lighter.

When you apply the finish, remember to do exactly the same to both sides or differential shrinkage problems will cause it to bow.