We test three categories of sharpening stones to find the best for putting a keen edge on your tools.

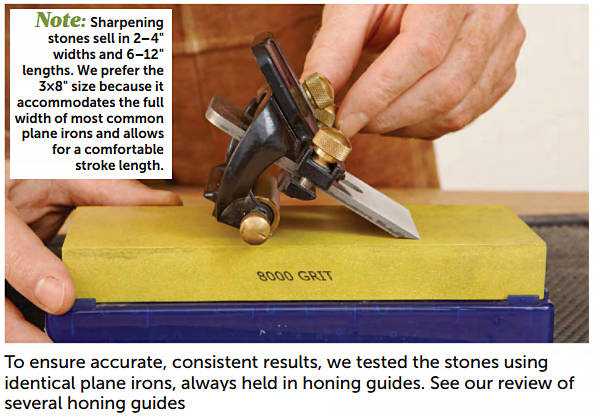

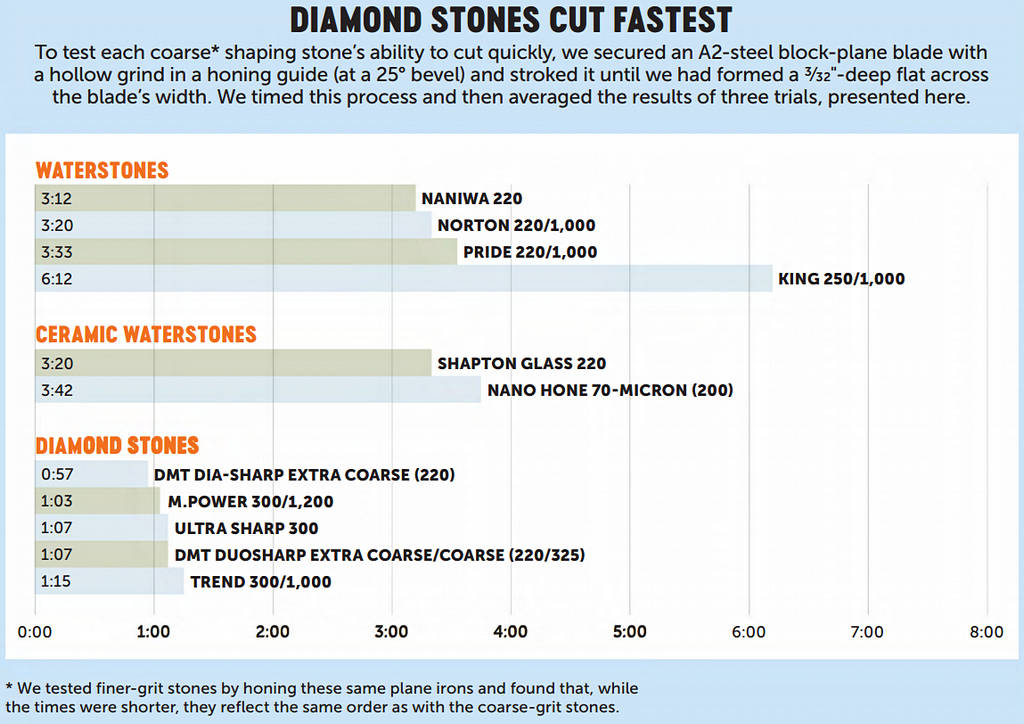

Sharpening stones remain our tried-and-true favorite sharpening medium for most hand-tool blades. They’re easy to use, require only human power, and sell for reasonable prices. But how do you know which stones to choose? We tested a variety of waterstones, ceramic waterstones, and diamond stones-11 sets ranging from 125-grit to 8,000 (more than two dozen stones in all)-to find the best fit for you. We flattened the stones that needed it, then sharpened chisels and plane irons, measuring the time it took for each as well as how much these stones dished out.

Sharpening stones remain our tried-and-true favorite sharpening medium for most hand-tool blades. They’re easy to use, require only human power, and sell for reasonable prices. But how do you know which stones to choose? We tested a variety of waterstones, ceramic waterstones, and diamond stones-11 sets ranging from 125-grit to 8,000 (more than two dozen stones in all)-to find the best fit for you. We flattened the stones that needed it, then sharpened chisels and plane irons, measuring the time it took for each as well as how much these stones dished out.

No matter which stones you select, you’ll need, ideally, three or four in progressive grits to shape and then hone blades to a perfectly sharp edge.

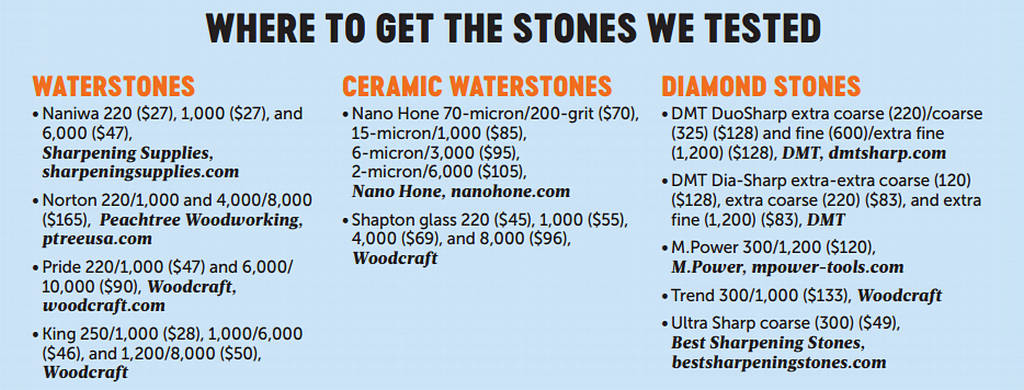

WATERSTONES: EFFECTIVE AND AFFORDABLE

- Waterstones typically consist of abrasive aluminum-oxide or silicon-carbide particles mixed with a binder that is heated and pressed into a rectangular block. The waterstones we tested cut slower than diamond stones, but about the same as ceramic waterstones.

- Waterstones wear quickly, exposing fresh grit to cut the steel. But because they’re softer, they also flatten more easily than other stones. (See examples of fast- and slow-wearing stones)

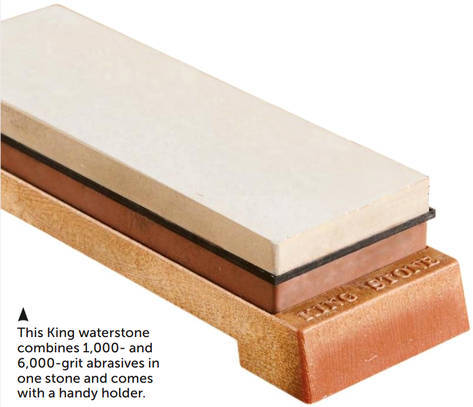

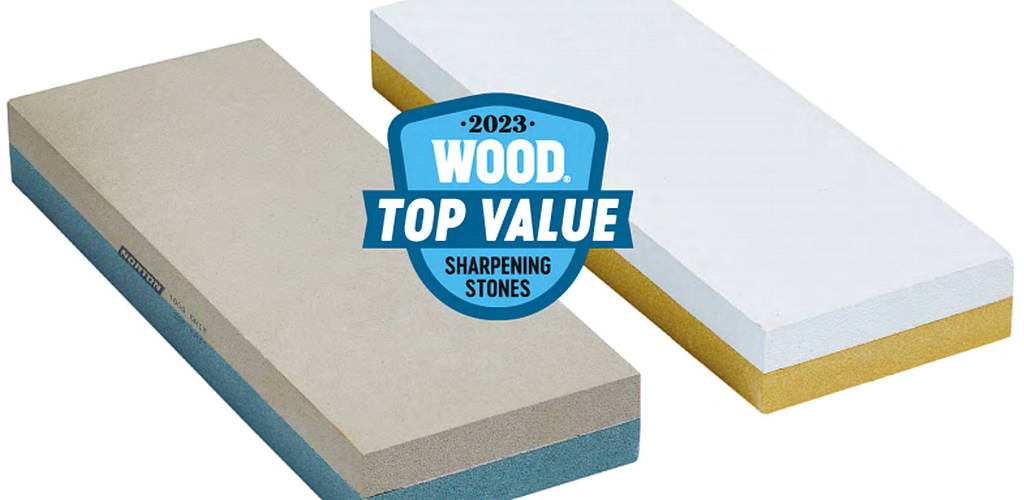

- You can get three to four stones for less than $170, making them the most affordable option. Two-sided stones, shown at left, save even more.

- Waterstones must soak for at least 15 minutes before use, a delay not required by other types we tested. Allowing wet stones to freeze or letting fine-grit stones (4,000 and up) soak long-term can cause them to break apart.

- Periodically dribble a little water on the stone during use to help it cut better and clear the slurry, known as swarf These stones tend to be the messiest.

CERAMICS: LESS WATER, LESS WEAR

Ceramic waterstones use similar ceramic particles, but are heated to a higher temperature than waterstones. We found that ceramics sharpen at about the same rate as most waterstones (next page) but wear at a much slower rate. Although you can find these as solid stones, most are bonded onto a glass or aluminum substrate to reduce the amount of ceramic material (to lower the price) and maintain flatness. Substrates do leave the backs of the stones slick, so plan to use a holder or grippy mat when sharpening.

Ceramic waterstones use similar ceramic particles, but are heated to a higher temperature than waterstones. We found that ceramics sharpen at about the same rate as most waterstones (next page) but wear at a much slower rate. Although you can find these as solid stones, most are bonded onto a glass or aluminum substrate to reduce the amount of ceramic material (to lower the price) and maintain flatness. Substrates do leave the backs of the stones slick, so plan to use a holder or grippy mat when sharpening.- Ceramic stones sell for about 50 percent more than comparable waterstones, and some cost the same as diamond stones.

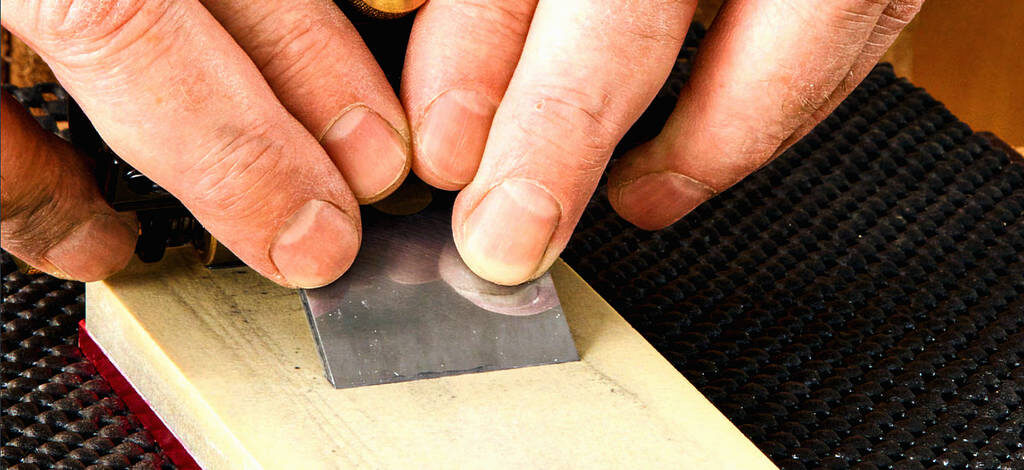

- Ceramics are ready to use immediately. Instead of soaking them in a water bath, just sprinkle or spray water onto them during use, as shown at left.

- Ceramics require less cleanup after sharpening: Just rinse and wipe dry.

DIAMONDS ARE A WOODWORKER’S FRIEND, TOO

- Diamond stones consist of tiny particles bonded onto a steel or aluminum plate. This ensures flatness and makes the “stone” less break-prone if dropped.

- In our testing, diamond stones cut the quickest of all types for both shaping and initial honing. But because they come only in grits from 120 to 1,200, you’ll need to supplement them with waterstones or ceramic stones of finer grits for final honing, making diamond stones the costliest option (for half the process).

- Whereas waterstones and ceramics are designed to wear away to reveal fresh abrasive, diamond proves less friable (easily broken down). Its hardness, combined with a rigid bond on the metal plate, means these stones don’t require flattening. You can even use a diamond stone to flatten waterstones and ceramics.

- As with the other stones, diamond stones require lubrication during use. While some call for proprietary lubricants, we found that water worked just as well. Be sure to rinse and wipe the stones when finished and allow them to dry thoroughly to prevent rust from forming on stones with steel plates.

- Diamond stones with empty spaces or patterns allow for swarf to gather and run off the surface during use. Solid-surface diamond stones, such as the Ultra Sharp and DMT Dia-Sharp, don’t do this. In our testing, we did not find a significant performance advantage for either style.

- Reducing abrasive with patterning reduces cost, and two-sided stones, such as the DMT DuoSharp in extra coarse/ coarse (220/325 grit, $128) add to that value by doubling the grits. By comparison, the single-sided DMT Dia-Sharp in extra-extra coarse (120 grit) costs the same $128 because it fully coats a single surface in diamonds.

DON’T GET IN A GROOVE: FLATTEN YOUR STONES

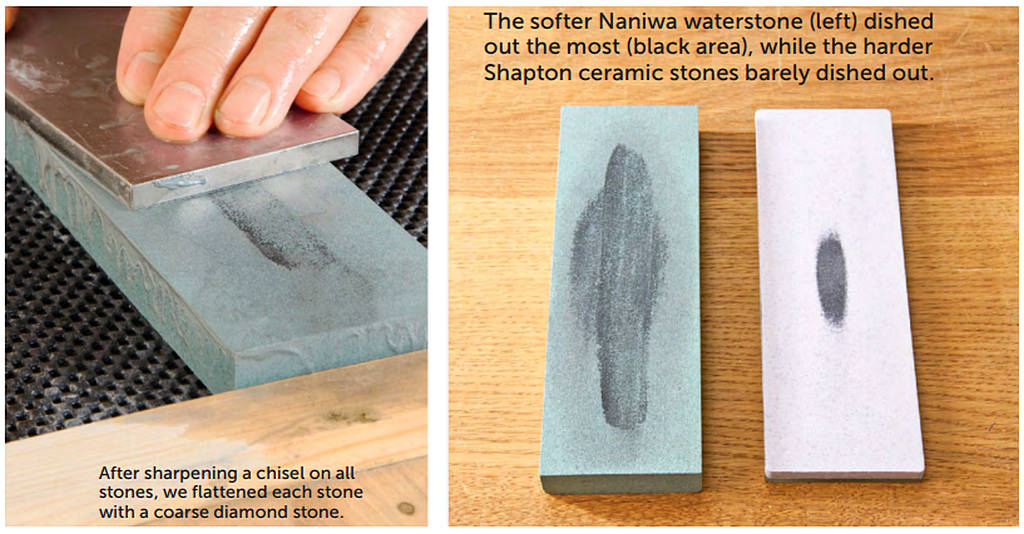

Waterstones and ceramic stones wear by design as the abrasive and binder break down to expose fresh abrasive particles. This keeps the stones working, but also means the stones dish out. So, you need to flatten these stones to prevent your tool edges from mimicking this dished-out shape. (Diamond stones, with their particle-on-metal construction, don’t need flattening.) We used a diamond stone to flatten dished stones, left, but you could also use a dedicated flattening stone.

To measure the dishing that occurs with each stone, we sharpened a 3/4″-wide chisel with a honing guide to equal sharpness on each stone. After cleaning away the swarf, we sprayed each stone with black guide coat-a product used in automotive body work to reveal imperfections when sanding. Then we made five flattening strokes on each stone, which revealed the extent of the dishing by the coating that remained, as shown above.

GET SHARP, STAY SHARP WITH THESE WINNING STONES

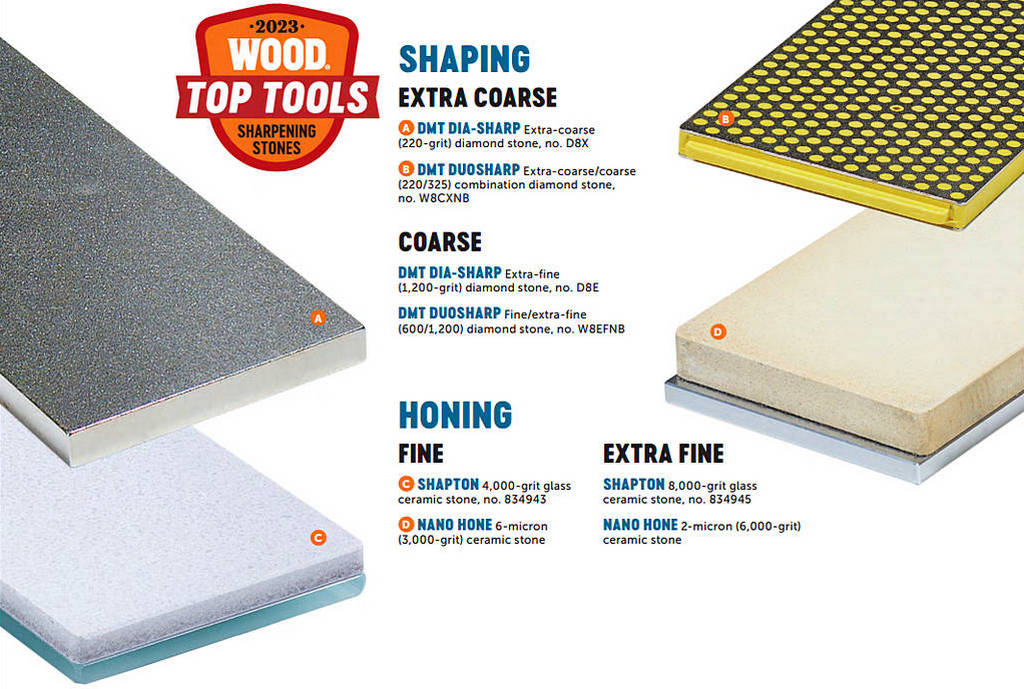

We appreciate very sharp tools, but we want sharpening to happen fast. That’s why, based on our tests, we prefer fast-cutting diamond stones for shaping and durable ceramic stones for honing. We couldn’t pick just one Top Tool, though, because we recommend you get stones in four grit ranges: You’ll want 220-325 for initial shaping and 1,000-1,200 for follow-up. Choose a 3,000-4,000 stone for initial honing and a 6,000-8,000 stone for final honing. Because we had virtual ties in our results, we named two Top Tools in each of these ranges.

If you’re working with a limited budget, consider the Top Value Norton combination waterstones in 220/1,000 and 4,000/8,000 grits. You get both in a kit with a flattening stone and plastic storage cases for $165.

HOW TO SHARPEN WITH STONES

Follow these simple steps to put a keen edge on any chisel, plane iron, or spokeshave blade.

START THE PROCESS BY SHAPING THE BEVEL

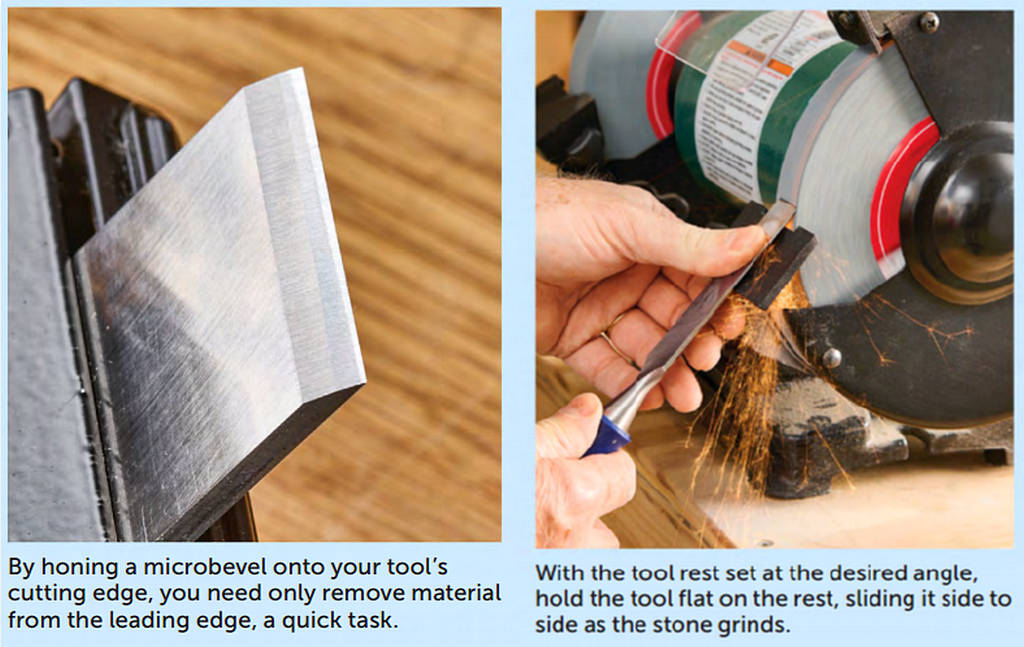

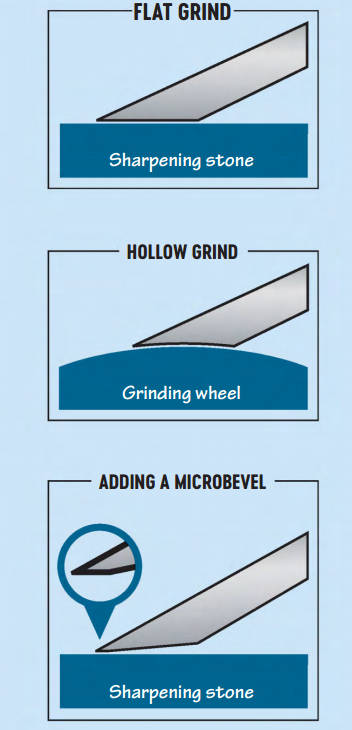

Sharpening consists of two steps: shaping and honing. During shaping you create the primary bevel angle on the cutting edge—usually 25° or 30°—with either a flat grind or hollow grind. You can use stones (120-325-grit) to create a flat grind, shown far right, by sharpening until the full depth of the cutting edge (front to back) is flat.

Even quicker, you can form a hollow grind at the bench grinder using a 100- or 120-grit aluminum-oxide wheel. Then shape the tool further on a coarse stone to create a narrow flat (about 1/16″) across the full width on the front and back of the bevel. The middle remains hollow, leaving less material to abrade away in subsequent honings. Return to this step as the bevel flattens.

A FEW POINTS:

A FEW POINTS:

- Diamond stones cut aggressively, leaving deeper scratches than waterstones and ceramics. This makes initial shaping faster, but adds a little more time to remove those scratches when you move on to finer-grit synthetic stones.

- When shaping a tool on a bench grinder, avoid overheating the tool, which can negatively affect the steel’s temper. Have a cup of water nearby to quench the tool often.

NOW HONE TO A KEEN EDGE

With the primary bevel established, move on to honing at the same bevel angle. On a 1,000- or 1,200-grit stone, stroke the blade as needed to remove the scratches left from the coarse stone. Repeat the process with 4,000 and 8,000 stones until the bevel has a mirror finish.

Some woodworkers prefer to add a microbevel, which is a very thin bevel at a 3-5° steeper angle along the cutting edge, as shown at left. A microbevel doesn’t make the edge sharper than a flat bevel. It does, just like a hollow grind, leave a smaller area to hone, making subsequent honings faster.

A FEW POINTS:

- You can usually hone a blade multiple times before you need to return to the coarse stones to reshape the bevel.

- If a manufacturer doesn’t offer a 4,000- or 8,000-grit stone, there’s a good chance they make 6,000 and 10,000, and these will substitute nicely.

- Fine-grit stones tend to be softer than coarse stones, so treat them gently to avoid tool gouges or chipped edges.

- Manufacturers use the designations “coarse” and “fine” differently when referring to their own products, so be sure to look for the grit rating to know what you’re actually buying.